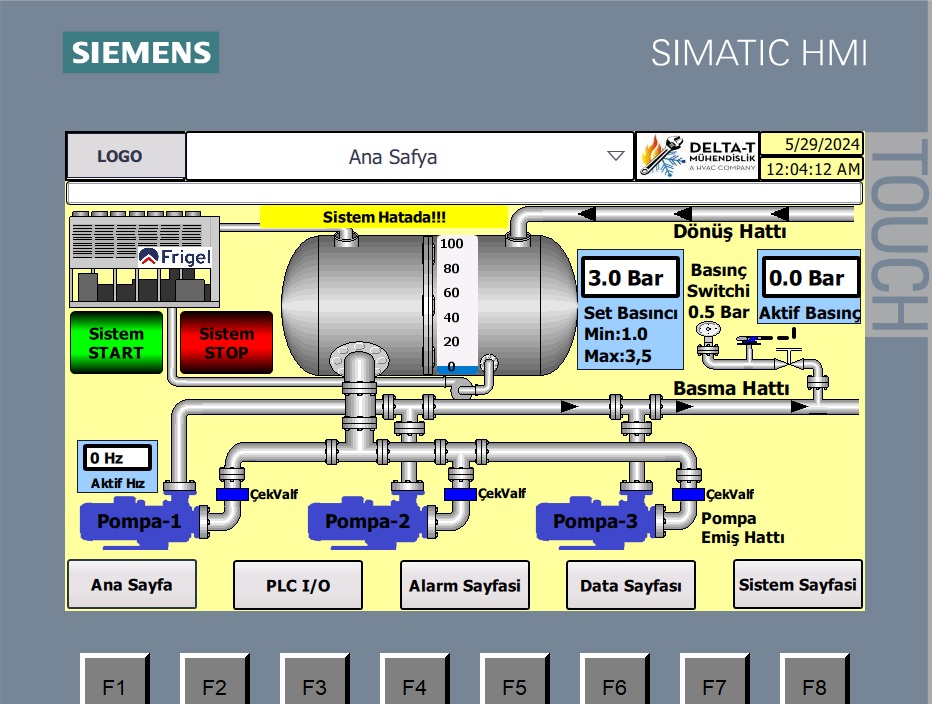

With an example from a pump house we designed and projected;

How should the HMI interface be in an automation system?

-Automations are special because they belong to each process, I will not go into the details of this process. An automation system should actively protect all equipment elements within its own structure and should always have a second protection.

-In systems with two protections, in this example, it is tried to prevent running without water with one pressure switch and level. Since it affects the whole factory, the ability to bypass one of the two protections with the yellow andon lamp was requested. Thus, factory downtime was minimized. Bypass features are a must.

-HMI should be simple, understandable and user friendly. Usually a technical staff will not use this screen. Therefore, our design should be simple.

-Auxiliary buttons must be used on the main page. In other words, let's say you have assigned page transition to the buttons on the panel used, it should not disrupt production because one of those buttons is broken. Under the name of the main screen, selective page transition, buttons and the panel's own buttons are used.

-It will be advantageous to use it as a template in alarm line systems. You can easily see the last incoming alarm pop up, unnecessary opening of the alarm message screen is prevented.

-The company that makes the design must put its logo. For information and contact.

-The time must be included. Date information can be optional.

-Alarm buffer, that is, the screen where we can see past alarms, must be present. I'm not even talking about instant alarms.

-When integrating to the field, the information of the surrounding machinery and equipment in the field should be included. For example, there is a Frigel chiller in the picture.

-Equipment visualization must be used. In other words, studies such as green when the pump is running, blue when it stops, or yellow in gray warning and red in error will show the design very well.

-Remember that all equipment, including the pipes used, are objects, so each object has a name. Check valve, pump 1,2,3 etc.

-All equipment brands and codes used are specified under separate Data Sheet. Such as EBARA pump Code CDX. Driver C2000 Delta 11kW etc etc.

-PLC IO map must be given. Concepts such as NC and NO used in the system should be clearly mapped.

-If the panel supports it, it will be very nice to assign an electrical project to the system.

-There should be instructions.

-In a hydraulic design, it should be shown on the hydraulic project.

-Under the name of the system page, the settings of your panel should be accessible to authorized personnel with a password. For example, it will always be logical to change the PID gain setting from the screen and make the page encrypted and protect it. Unauthorized personnel will not intervene.

So to summarize briefly, the operator panel is an interface. It is necessary in such systems. We need to think simple, design simple and get maximum benefit.